The most suitable machine to cut the cardboard of a thickness of less than 8mm!

To cut cardboard up to 8mm, which is often used in cardboard folding carton industry.And at even lower price than the AS series, it was to facilitate the entry into the small-lot production.

Z Series Features

1. easy to introduce low price! Option in the expansion is also possible!

“Price which is easy to introduce than AS series, we want this product.”

“Price which is easy to introduce than AS series, we want this product.”

Z Series In response to the needs of such customers has emerged.By limiting the corresponding material to the following cardboard and folding carton 8mm, we have developed a high-performance, high-quality machines at a low price.Further, by combining the options, you can be a scalable functionality.

2. The exact borders and cutting by high-performance timing belt system and strongly hard head.

We’re using is not timing belt system to a conventional cutting machine.It is a high precision, can be a long time used in addition.

The head gained the stable performance with emphasis on the balance of operation and intensity.

3. High quality guaranteed! Long life carbide blade and Japanese parts!

Durability of conventional blade decrease when used in high speed.I prepare a domestic self-developed, abundant blade to support various materials.We can design blade.

Durability of conventional blade decrease when used in high speed.I prepare a domestic self-developed, abundant blade to support various materials.We can design blade.

4. high strength and high accuracy by the improvement of aluminum honeycomb board!

In conventional plate the swell of the plate needs to be adjusted at regular interval.So thick and heavy plate should be used.Therefore, we have adopted a high-performance aluminum honeycomb board.

It has high durability with respect to the weight.In addition, taking advantage of the structure of the hexagonal column.It is possible to by sucking the material at the blower from the hole, while suppressing the deviation.

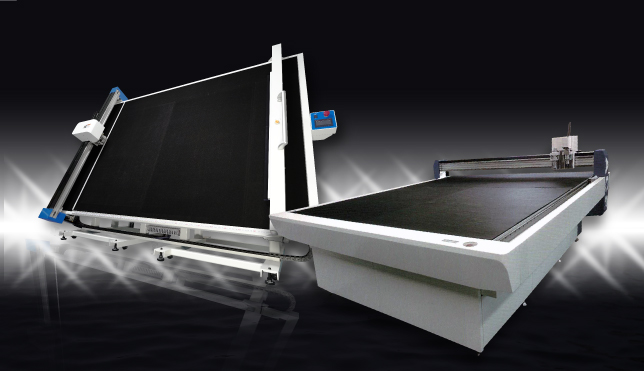

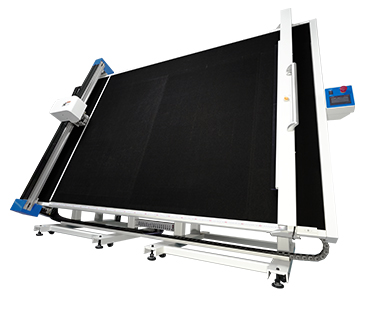

The vertical machine for space-saving!

We developed a vertical (stand-type) cutting machine.For the effective use of space.Footprint is about two-thirds of the flat type.If you are planning for the introduction of a space-saving vertical type is recommended.Moreover,the vertical machine is available in Japan.

We developed a vertical (stand-type) cutting machine.For the effective use of space.Footprint is about two-thirds of the flat type.If you are planning for the introduction of a space-saving vertical type is recommended.Moreover,the vertical machine is available in Japan.

Specifications

We offer the various types of work size.Also size other than the following can be developed and manufactured as a special order.

※alphabet at the end of the model name represents the type of model. F is flat, S is vertical, W is twin arm・two head.

| Machine name (flat type) |

Work size | The dimensions of the flat type (mm) | Weight (kg) |

|---|---|---|---|

| ASZ1209F | 1200×900 | 1750×1410×1120 | 250 |

| ASZ1812F | 1800×1200 | 2310×1810×1170 | 300 |

| ASZ2016F | 2000×1600 | 2570×2120×1170 | 400 |

| ASZ2612F | 2600×1200 | 3170×1810×1170 | 500 |

| ASZ2616F | 2600×1600 | 3170×2120×1170 | 550 |

| ASZ2916F | 2900×1600 | 3460×2120×1170 | 600 |

| ASZ3020F | 3000×2000 | 3460×2440×1170 | 650 |

| Machine name (vertical type) |

Work size | The dimensions of the vertical type (mm) | Weight (kg) |

| ASZ1209S | 1200×900 | 1750×1240×1930 | 250 |

| ASZ1812S | 1800×1200 | 2530×1240×1930 | 300 |

| ASZ2016S | 2000×1600 | 2660×1320×2160 | 400 |

| ASZ2612S | 2600×1200 | 3260×1240×1930 | 500 |

| ASZ2616S | 2600×1600 | 3260×1320×2160 | 550 |

| ASZ2916S | 2900×1600 | 3550×1320×2160 | 600 |

| ASZ3020S | 3000×2000 | 3810×1310×2480 | 650 |

| Z Series Mechanical performance | |||

| Maximum speed | 1100mm/s | ||

| Maximum acceleration | 0.8G | ||

| Positioning accuracy(mm) | ±0.2mm | ||

| Repetition accuracy(mm) | ±0.05mm | ||

| Adaptation material | Cardboard , paper and foam material other all materials | ||

- DXF processing software “CUT Assist” is provided free of charge to all models

- “Repeat function”, “automatic vacuum ON / OFF function” is standard function for all models

You can see also sample cut page of the list.view sample cut page.learn more

Options Specifications

Please use the options in order to optimize a machine to meet your needs.

| Option | Feature Description |

|---|---|

| Borders tool for plastic cardboard | Can be ruled put in plastic cardboard up to 5mm |

| cropmarks automatic recognition | By recognizing the cropmarks automatically, cutting while correcting a print |

| Pen tool | Customization and software development is also possible |

The important thing is after-sales service.

We think “true association starts after product purchase.”

We think “true association starts after product purchase.”

After-sale service is prepared so that the costomer of various countries can also be satisfied.

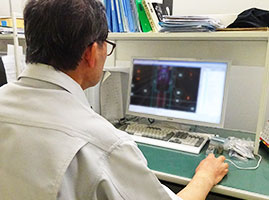

Software Development and Customization of machines.

In our cutting machine it is equipped with ACS own software CUT Assist as standard.If the data type is DXF, it can be cut using this software.As we recommended other, there is also such as software “rapid cut” that can be cut using a CAD software.

In our cutting machine it is equipped with ACS own software CUT Assist as standard.If the data type is DXF, it can be cut using this software.As we recommended other, there is also such as software “rapid cut” that can be cut using a CAD software.

If there is a request to the other, we are also possible the development of software that is tailored to customize and it’s machine.